FAQs & Maintenance Tips

-

Types of Heat Exchangers: A Comprehensive Guide for All Industries

Heat exchangers, undeniably crucial devices, shift heat from one fluid to another, without any direct touch between the fluids. Their essential nature shines in industries dealing with heating, power plants, chemical processing, and more. Interestingly though, rather than being a singular device, heat exchangers diversify themselves into plate heat exchangers, shell and tube, and compact…

-

The Most Effective Heat Exchanger: A Comprehensive Comparison Guide

No single heat exchanger can be pinpointed as “the most effective” without considering the specific application in question. Each type, whether it’s a plate heat exchanger, shell and tube exchanger, or a dimple plate type, has its unique merits and fields of effectiveness. For example, plate heat exchangers are compact and efficient, making them the…

-

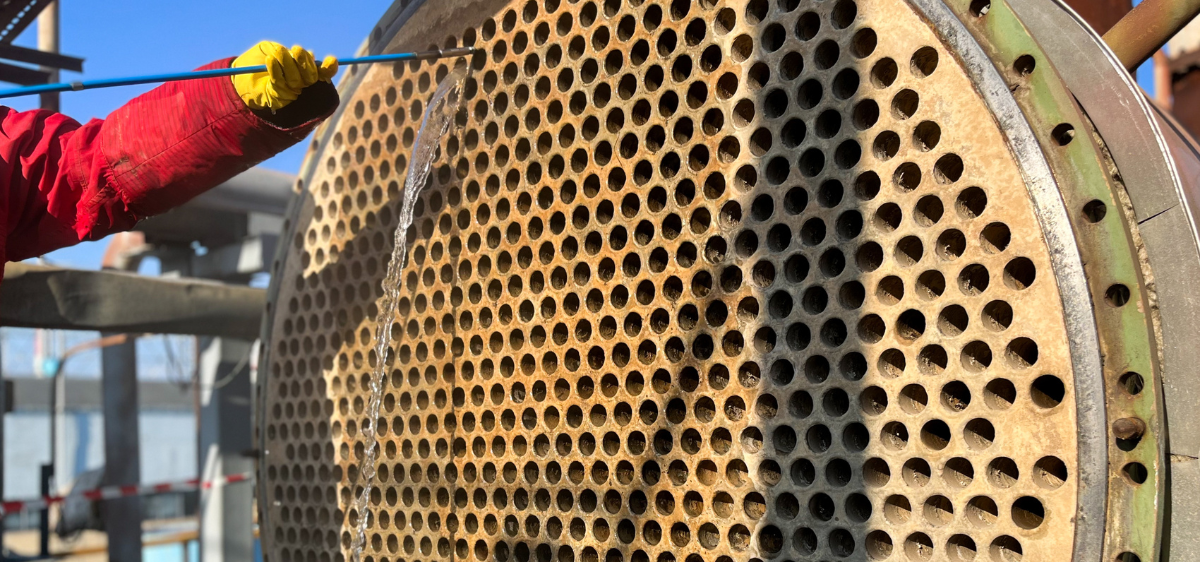

Effective Chemicals for Cleaning Heat Exchangers: A Comprehensive Guide

Various chemicals like alkaline detergents, acidic detergents, and synthetic or mineral oils are used to clean heat exchangers. These different chemicals each have a unique job in removing built-up gunk from the surfaces inside the exchanger. Alkaline detergents play a huge part by making this stuck on dirt easier to get rid of especially when…

-

Signs of a Bad Heat Exchanger: How to Troubleshoot and Replace

Recognizing a faulty heat exchanger lies in understanding certain abnormal happenings. A sudden hike in heating bills without obvious reasons, inconsistent warmth, odd smells, and noticeable soot near the furnace often suggest problems with the heat exchanger. This might come as a surprise, but various flame tints inside the combustion chamber can also indicate an…

-

How Does a Heat Exchanger Work? Exploring Function and Types

A heat exchanger works on a simple principle: moving heat from one liquid to another without mixing them. They stand close, they exchange warmth, but they never touch. Our store provides these vital guards – gaskets, plates, and tubes – that keep the change running smoothly and prevent any unintentional meeting. Now, think about this…

-

How Much Does an Industrial Heat Exchanger Cost? Pricing, Types, and Budgeting

An industrial heat exchanger’s cost can range significantly, driven by several critical factors. These key elements include design pressure, metallurgy, tube size, as well as the specific type of joint design and nozzle configuration chosen. With larger sizes and more complex designs typically resulting in higher prices, one could expect costs ranging from about $1…

-

Exploring the Most Popular Heat Exchanger Type: An Industry Perspective

Shell and tube exchangers rule the roost in industries. Their sturdy build, adaptability and capacity to manage tough conditions make them a favoured choice. Yet, it’s not just about robustness or adaptability. These devices also shine for their efficiency, handling high temperatures and pressures like a champ. Now, let’s dive into the ins and outs…

-

Xylem Charlotte NC: Water Treatment Solutions and Services

Xylem grants Charlotte a breath of fresh life with their innovative water technology solutions. They provide items such as pumps, mixers, and treatment systems that meet various industrial needs. But the story doesn’t end there; Xylem also co-operates with local groups and businesses to craft unique strategies for water management. This detail is vital because…